Reliable Cooling for Industrial Operations

Schedule Chiller Services in Clinton, serving all of Central NY

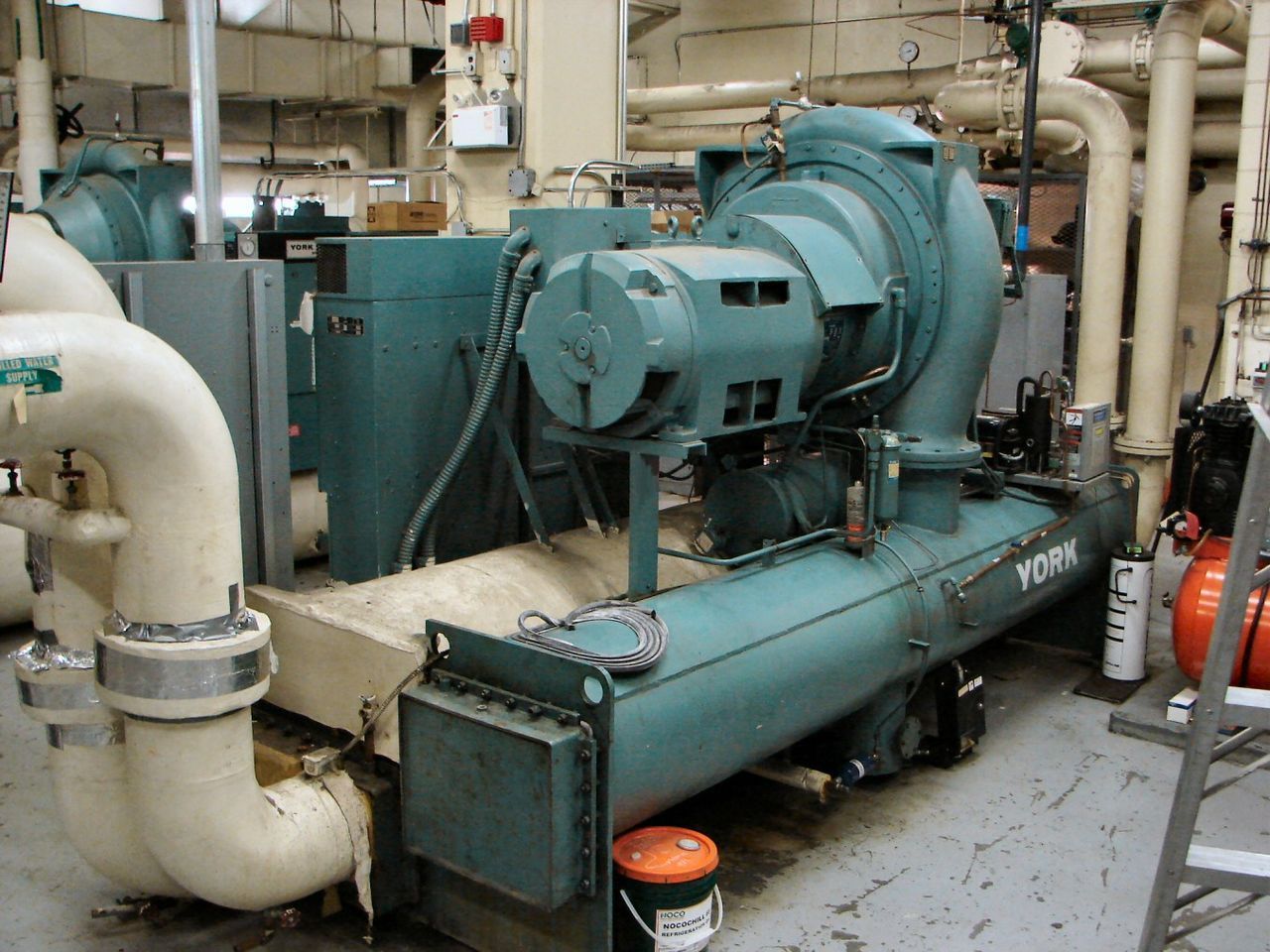

Your facility in Clinton or Central NY depends on consistent cooling capacity to support critical operations, and when chiller systems fail, the impact spreads quickly across production schedules and operational timelines. Stephen S. Starr Mechanical Corp delivers comprehensive chiller system solutions, including maintenance, repair, replacements, compressor rebuilds, and full chiller plant operations tailored to the demands of industrial sites, healthcare facilities, and educational institutions throughout Clinton and Central NY.

Our technicians use industry-standard diagnostic tools and testing methods to extend equipment life and optimize efficiency, addressing the needs of facilities that rely heavily on chilled water for operations. We support process cooling equipment and ice rink systems that require precise temperature control and reliable year-round performance, ensuring quiet, efficient, and consistent chiller performance using proven repair and rebuild techniques.

Start protecting your Central NY facility's cooling infrastructure with a comprehensive chiller services assessment today.

What to Expect When You Book

When you schedule chiller services in Clinton or Central NY, you begin with a detailed inspection that identifies mechanical wear, refrigerant charge levels, and overall system performance under current operating conditions. Our technicians arrive equipped with calibrated diagnostic tools designed to measure compressor function, thermal efficiency, and control system accuracy, ensuring every component meets the performance standards your facility requires.

Stephen S. Starr Mechanical Corp provides support for nearby cities and commercial corridors where large buildings depend on central cooling systems. Comprehensive chiller plant operations include compressor rebuilds that restore original capacity and eliminate the noise and vibration caused by worn internal components.

You receive a detailed report outlining current system health, recommended repairs, and options for ongoing maintenance programs that prevent uninterrupted cooling and reduce the risk of emergency breakdowns during peak demand periods. Our service approach addresses both immediate mechanical issues and long-term equipment reliability, helping you plan upgrades or replacements before failures disrupt operations.

Key Benefits of This Service

Understanding how chiller services support your facility helps you make informed decisions about maintenance timing, repair priorities, and system upgrades that align with your operational goals and budget constraints.

Absolutely. We work with facilities across Clinton and Central NY that require process cooling, precision temperature control for medical equipment, and continuous operation for manufacturing processes.

Our technicians provide clear communication throughout every service visit, explaining findings and recommendations in straightforward terms that support your decision-making process. Reach out to our team to establish a maintenance program that keeps your chiller systems running efficiently year-round.